Resources

Special Finishes

Make your print stand out with special finishes

When you want your printed material to do more than just deliver information, special finishes can help you create a piece that stands out and leaves a lasting impression. From subtle texture to eye-catching shine, the right finishing technique can add value, reinforce your brand, and turn a simple print project into something people want to keep.

Here’s a practical guide to some of the most effective special finishing options, and what they’re best suited for.

HIGHLIGHT WITH GLOSS

Spot UV

Spot UV is a coating process where a high-gloss varnish is applied to specific areas of the print using a UV (ultraviolet) light to cure it. This method creates a sharp contrast between the glossy areas and the matte surface, making the highlighted regions stand out.

Spot UV is ideal for smaller areas where you want to create a dramatic visual effect without covering the entire surface. The most common applications are on logos, headlines, or images.

MAKE IT SHINE

Foil Blocking

Foil blocking involves using a heated die to transfer metallic or pigmented foil onto specific areas of your design. The process uses heat and pressure to adhere the foil to the paper. Gold, silver, and copper are classic choices, but modern foils come in a wide range of colours and effects, including holographic and matte finishes.

Foil blocking is often done on high-end materials like invitations, packaging, or business cards, where it not only adds an aesthetic finish but also enhances the tactile experience. It’s highly durable, making it ideal for items that will be handled frequently.

texture & dimension

Embossing & Debossing

Embossing and debossing are both processes that create physical texture on the printed surface. Embossing involves raising specific parts of the paper or cardstock using a heated die and pressure, creating a three-dimensional effect.

Debossing, on the other hand, involves using a similar die technique, but instead of raising the design, it presses it into the paper, leaving a recessed impression.

Both techniques are commonly used on thicker stocks, as they require a paper material that can handle the pressure and retain the formed texture. These processes are especially effective on logos, titles, or other focal design elements, adding both visual and tactile appeal.

custom shapes

Die Cutting

Die cutting allows you to move beyond standard edges and shapes. It is a technique where a steel rule die is used to cut custom shapes or patterns into paper or card stock. The die can be made to any shape, from simple rounded corners to complex designs with intricate cut-outs, such as windows, custom-shaped packaging, or layered elements.

This method is ideal for materials where standard straight edges won’t create the impact you want. Die cutting is a practical way to add interest without overcomplicating the design, making it perfect for unique business cards, greetings cards, brochures, packaging, and promotional materials.

protect & enhance

Lamination

While not decorative in the same way as other finishes, lamination adds durability and a refined feel to your print. Lamination involves bonding a thin layer of plastic film to the surface of your print using heat and pressure. This process provides a protective coating that helps increase durability and resistance to moisture, dirt, and handling.

There are three primary finishes available for lamination: Gloss, Matte, and Soft-Touch. Gloss lamination gives your print a shiny, reflective finish, while matte provides a smooth, non-reflective surface. Soft-touch lamination has a velvety, tactile feel and adds a luxury element to your printed materials. Lamination is commonly used on high-use items like brochures, menus, and business cards, where you require both durability and aesthetic appeal.

Happy to help

Each special finish has its own technical advantage, whether it’s adding texture, durability, or a creating a visual focal point. Understanding how each process works, and when it’s best to use them, is key to maximising the impact of your print materials. When done correctly, these finishes don’t just look good, they perform well and help improve the overall quality of your product.

The best results come from considering them at the design stage, so they complement your content rather than competing with it. If you’re unsure about which finishes are right for your next project, we’re always happy to talk through options and make recommendations to suit your project, timeline and budget.

Other resources

Our A–Z glossary of printing terms to better understand key industry jargon and processes.

Discover standard paper sizes at a glance to choose the right format for your print project.

Calculate your book spine width in seconds using our handy online Spine Width Calculator.

Our cutter guide book includes over 100 capacity and non-capacity folder guides.

Download our quick guide to preparing print-ready files using Adobe InDesign.

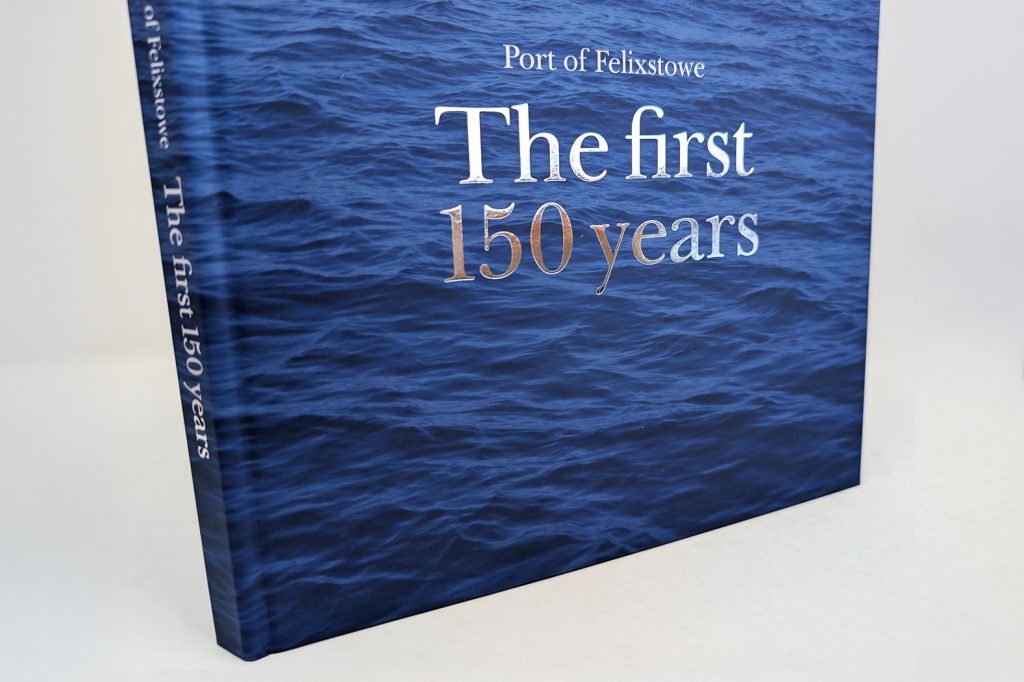

Explore optional extras and finishes for your hardback book printing project.