what we do

Print Finishing

print finishing

Hello possibility

At Page Bros, we are fully equipped with advanced binding and stitching lines to accommodate a wide range of formats and styles. From saddle-stitched brochures to perfect-bound books, the possibilities of paper are endless.

For a special touch, we offer premium finishes such as lamination for protection and sheen, metallic foil-blocking for standout detail, precision die-cutting for custom shapes, embossing and debossing to add texture and dimension, and spot UV to highlight key elements with gloss varnish.

The right finish not only protects and enhances your printed piece, it defines the final impression it leaves. Whether you’re aiming for polished and practical or bold and bespoke, we have the tools and expertise to bring your vision to life.

perfectly bound

Binding Options

When it comes to printed materials, the binding you choose is more than just a finishing touch. Binding determines how your project looks, feels, and holds up over time. From simple brochures to premium publications, understanding the main types of binding can help you achieve the right balance of appearance, durability, and cost.

BEST FOR SMALLER DOCUMENTS

Saddle Stitching

Saddle stitching is one of the most popular methods for booklets, brochures, and small magazines. Sheets are folded and stapled along the spine, creating a neat and lightweight product.

It’s an efficient choice for print projects up to around 64 pages, offering a fast turnaround and low production cost. Saddle stitching is ideal for mailouts, handouts, or short-term use materials that need to be easy to distribute.

BEST for larger documents

Perfect Binding

Perfect binding is commonly used for thicker books, annual reports, and high-quality magazines. The pages and cover are glued together at the spine, creating a square edge that looks clean and polished.

It’s ideal if you want a publication that feels substantial and professional, with the added benefit of displaying a spine title on a shelf for easy identification and a more refined appearance.

BEST FOR HEAVY USE

PUR Binding

PUR binding is similar to perfect binding but uses a stronger adhesive (Polyurethane Reactive). This makes it a smart choice for publications that will be handled frequently, like product catalogues or manuals.

The flexible, durable spine means pages stay secure, even with heavy use, and the superior glue strength also allows for better performance with coated or heavy-weight papers. Additionally, PUR-bound books can open flatter than traditional perfect-bound ones, improving readability and user experience.

PRACTICAL AND EASY TO USE

Wire or Spiral Binding

Wire and spiral binding allow pages to open flat or fold back on themselves, making them practical for notebooks, training manuals, and reference guides. Wire binding uses metal loops available in various sizes and colours such as black, white, and silver, while spiral binding typically uses coloured plastic coils.

This style is especially useful when usability is a priority. For example, in workbooks or cookbooks that need to stay open on a surface, or hanging wall calendars.

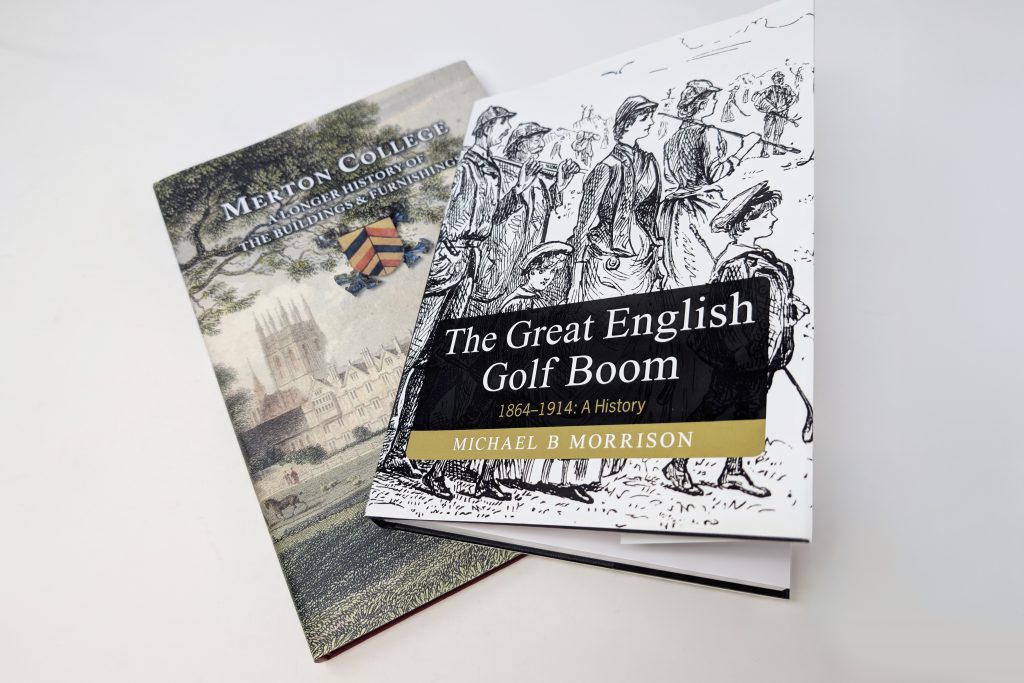

HARDBACK QUALITY & LONGEVITY

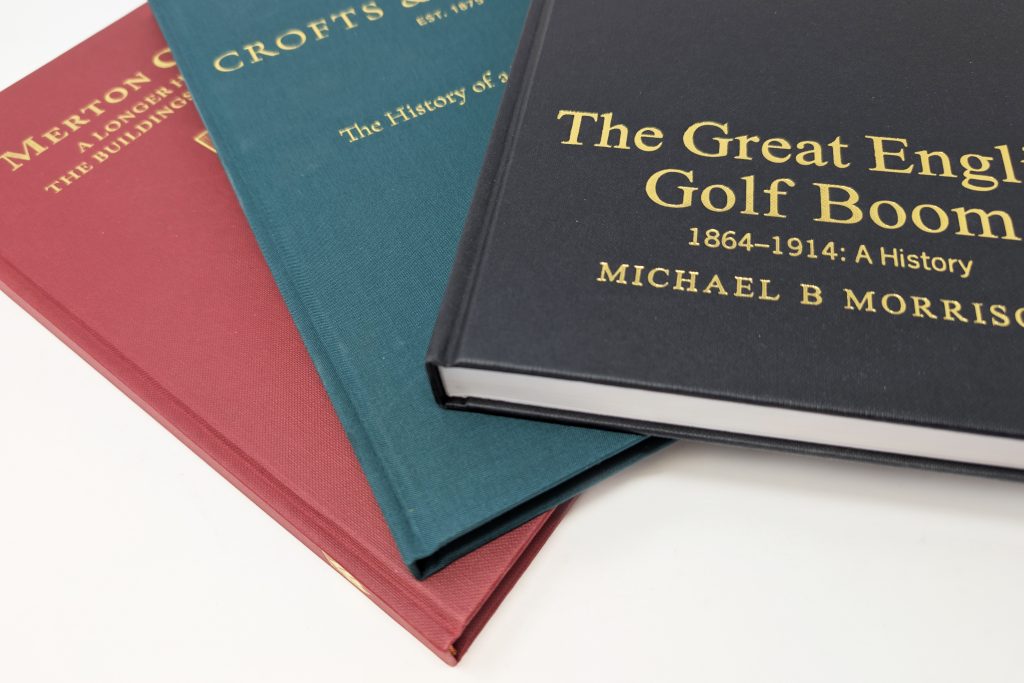

Case Binding

For a premium finish and long lifespan, case binding is the traditional choice. Pages are gathered in sections, sewn together, and attached to a hard cover. There are many ways to customise your hardback book including printed dustjackets and endpapers, head and tail bands and ribbon markers.

Case binding is used for hardcover books, corporate publications, and any project where durability and presentation matter.

a case for hardbacks

Hardback Book Extras

Hardback books are designed to last, and the finishing touches you choose play an important role in how they are received and remembered. From practical features like ribbon markers and head and tail bands, to decorative details such as foil blocking, cloth covers, or printed endpapers, each option contributes to the overall look and feel of the book. For special editions or presentation volumes, extras like dust jackets, belly bands, slipcases, or boxes provide an additional level of protection and distinction.

a decorative detail

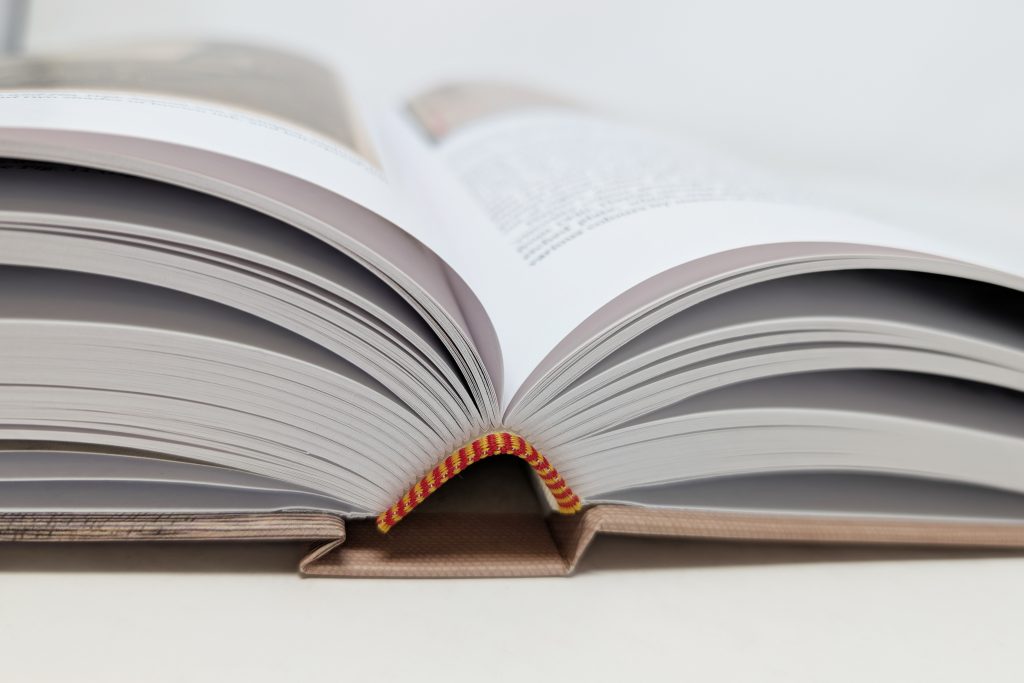

Head & tail bands

Head and tail bands are the small strips of coloured material, typically woven from coloured twine, you see at the very top and bottom of the spine. Originally, they were sewn in by hand to reinforce the binding and protect against wear. Today, while much of the binding process is mechanised, head and tail bands are still added for both strength and appearance.

They are available in a range of colours and styles and give the book a “finished” look, particularly when matched with cover, ribbon marker or endpaper colours.

marking your place

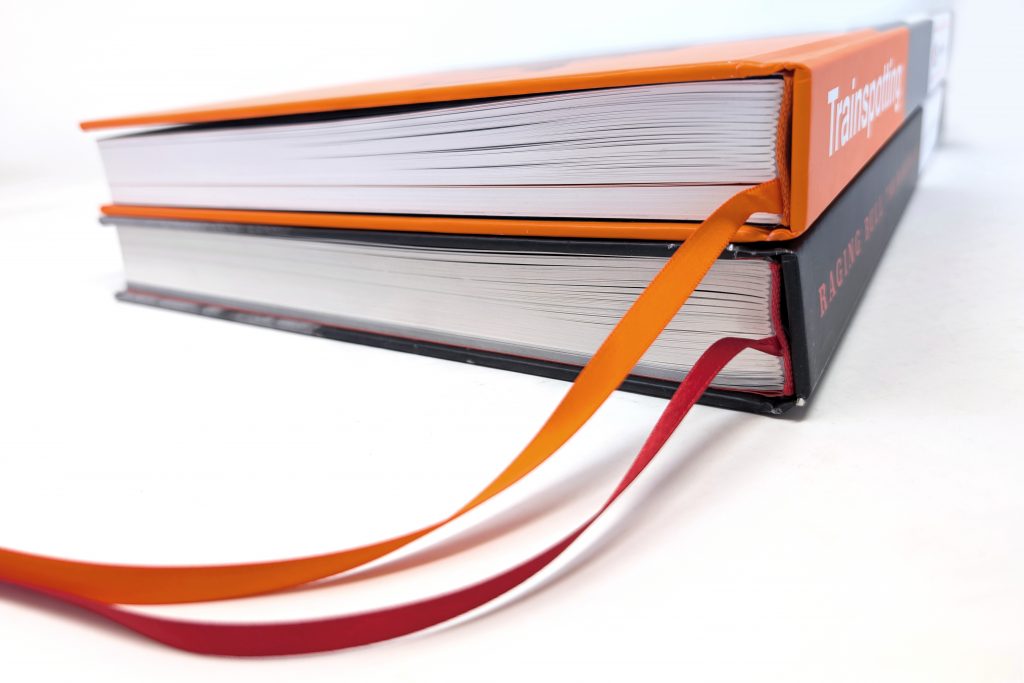

Ribbon markers

Ribbon markers are one of the most practical extras available. A ribbon is fixed into the spine and lies between the pages, giving the reader a convenient way to mark their place. They are often used in Bibles, reference works, or annual reports, but can add value to almost any hardback.

They come in a wide range of colours, so it’s easy to coordinate with other design choices. Multiple ribbons can also be added if the book is likely to be used for study or cross-reference. The ribbon ends are heat sealed to keep the cut edge neat for long-term use.

setting the tone

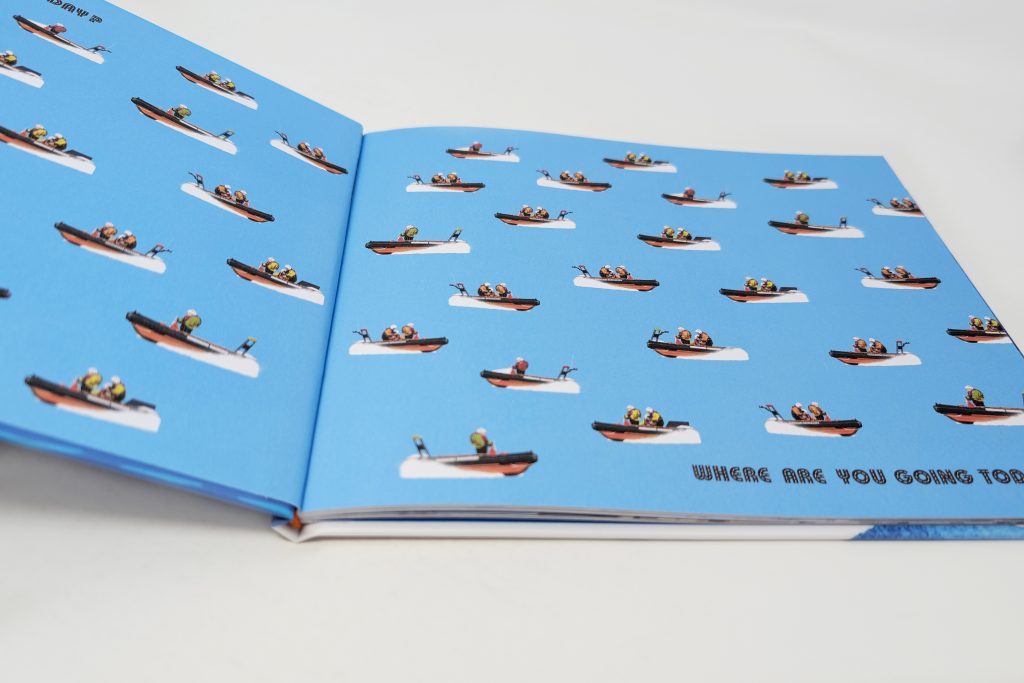

Endpapers

Endpapers are the sheets that attach the cover boards to the book block, often heavier than the rest of the text paper and can be coloured paper or printed.

They are often the first pages a reader sees when opening the book. They offer scope for design creativity, setting the tone before the main content begins. Common examples include printed maps, timelines, patterns, or brand colours.

Because they are large and visible, printed or coloured endpapers help make the book feel complete and considered. We recommend a sturdier uncoated stock for endpapers and keeping fine detail away from the hinge for a clean, durable fold.

a timeless finish

Cloth covers

Cloth has been used for centuries to bind books, and it remains a popular choice for hardbacks. Woven materials such as linen or buckram create a tactile and traditional surface that feels durable and timeless. Cloth covers can be paired with foil stamping or blind debossing for titles and logos, allowing you to keep a classic look with understated detailing.

This option is particularly well suited to special editions or books intended to last for many years.

contrasting textures

Quarter binding

Quarter binding is where the spine (and sometimes the corners) of the case are covered in a different material to the rest of the boards. A common approach is to use cloth or leather on the spine for strength, with printed paper or another cloth across the front and back boards.

This technique dates back centuries and was originally used to reinforce the most vulnerable areas of the book. Today, it is chosen for its classic appearance and the scope it offers for contrasting textures and colours.

present & protect

Dustjackets & bellybands

Dust jackets and belly bands are both effective ways to enhance a book’s protection and presentation.

A dust jacket is a full-height covering with flaps, printed on paper and wrapped around the cover. It adds an extra layer of protection while providing additional space for design, with inside flaps often carrying blurbs, author biographies, or other supplementary information.

Belly bands, by contrast, are narrow printed strips wrapped around the middle of the book and sealed, with no flaps. They’re often used for promotional purposes, such as highlighting a new edition or an award, and can easily be removed after purchase.

Both options serve as versatile tools to elevate the appearance of a book and support marketing efforts.

for something special

Slipcases

Slipcases are open-ended sleeves made from board, often wrapped in paper or cloth to match the book. They provide hardback books with extra protection and help to enhance the look of the finished product. They also protect against dust and light while presenting the book smartly on a shelf.

Boxes are often used to house several books together, such as a series or collection. Options include thumb-cuts for easy extraction, internal linings and foil to the case. Heavier sets benefit from thicker board for rigidity.

Make an impression

Special finishes

When you want your printed material to do more than just deliver information, special finishes can help you create a piece that stands out and leaves a lasting impression. From subtle texture to eye-catching shine, the right finishing technique can add value, reinforce your brand, and turn a simple print project into something people want to keep.

highlight with gloss

Spot UV

Spot UV is a coating process where a high-gloss varnish is applied to specific areas of the print using a UV (ultraviolet) light to cure it. This method creates a sharp contrast between the glossy areas and the matte surface, making the highlighted regions stand out.

Spot UV is ideal for smaller areas where you want to create a dramatic visual effect without covering the entire surface. The most common applications are on logos, headlines, or images.

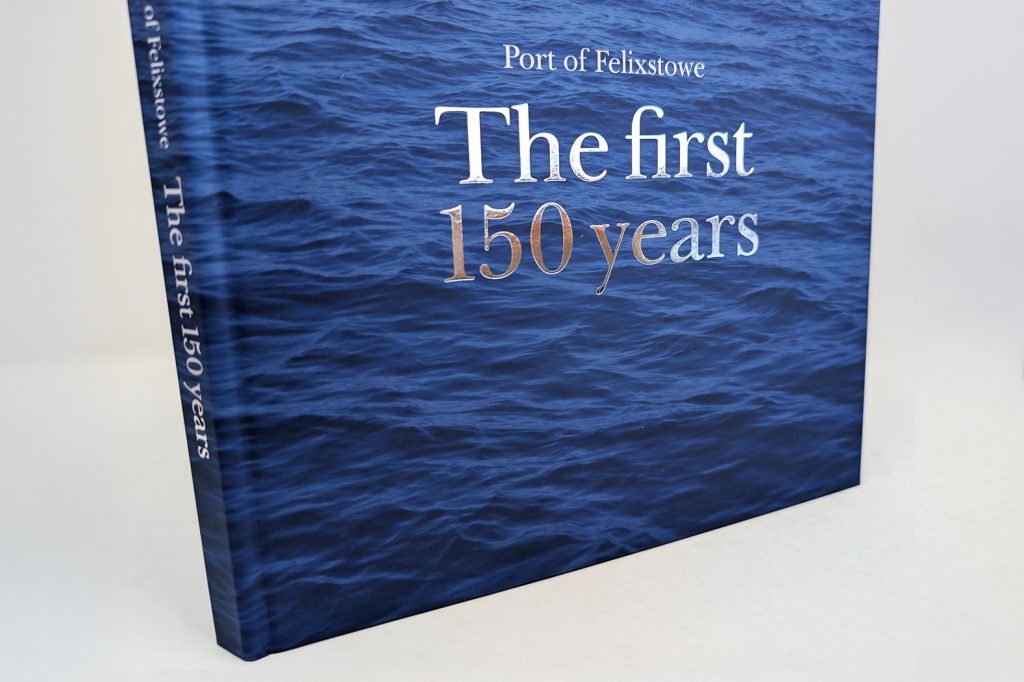

MAKE IT SHINE

Foil Blocking

Foil blocking involves using a heated die to transfer metallic or pigmented foil onto specific areas of your design. The process uses heat and pressure to adhere the foil to the paper. Gold, silver, and copper are classic choices, but modern foils come in a wide range of colours and effects, including holographic and matte finishes.

Foil blocking is often done on high-end materials like invitations, packaging, or business cards, where it not only adds an aesthetic finish but also enhances the tactile experience. It’s highly durable, making it ideal for items that will be handled frequently.

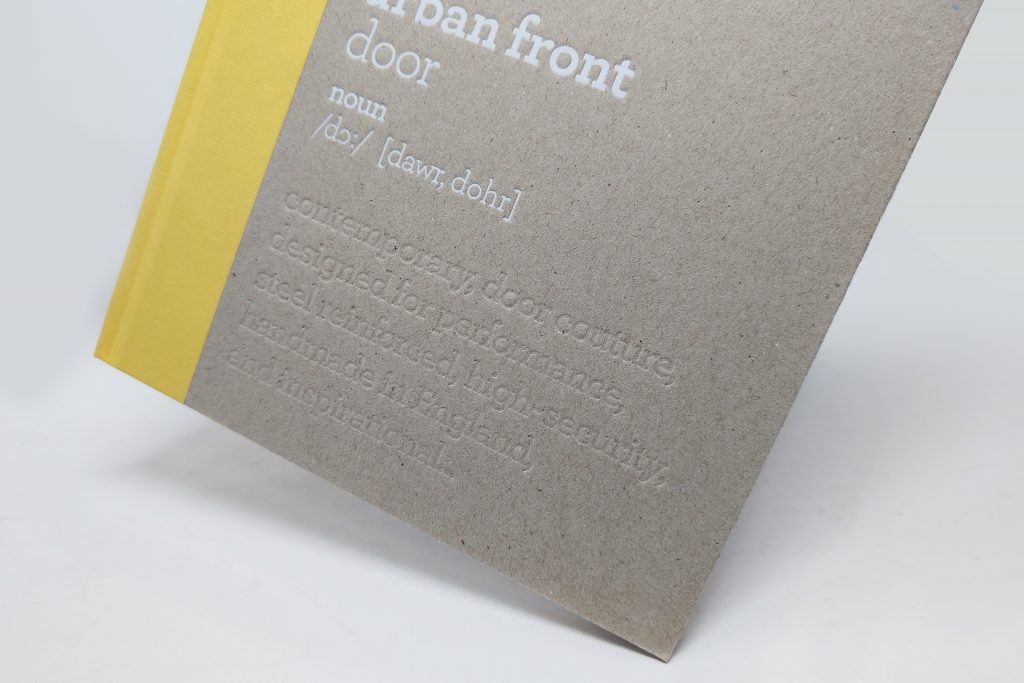

texture & dimension

Embossing & Debossing

Embossing and debossing are both processes that create physical texture on the printed surface. Embossing involves raising specific parts of the paper or cardstock using a heated die and pressure, creating a three-dimensional effect.

Debossing, on the other hand, involves using a similar die technique, but instead of raising the design, it presses it into the paper, leaving a recessed impression.

Both techniques are commonly used on thicker stocks, as they require a paper material that can handle the pressure and retain the formed texture. These processes are especially effective on logos, titles, or other focal design elements, adding both visual and tactile appeal.

custom shapes

Die Cutting

Die cutting allows you to move beyond standard edges and shapes. It is a technique where a steel rule die is used to cut custom shapes or patterns into paper or card stock. The die can be made to any shape, from simple rounded corners to complex designs with intricate cut-outs, such as windows, custom-shaped packaging, or layered elements.

This method is ideal for materials where standard straight edges won’t create the impact you want. Die cutting is a practical way to add interest without overcomplicating the design, making it perfect for unique business cards, greetings cards, brochures, packaging, and promotional materials.

protect & enhance

Lamination

While not decorative in the same way as other finishes, lamination adds durability and a refined feel to your print. Lamination involves bonding a thin layer of plastic film to the surface of your print using heat and pressure. This process provides a protective coating that helps increase durability and resistance to moisture, dirt, and handling.

There are three primary finishes available for lamination: Gloss, Matte, and Soft-Touch. Gloss lamination gives your print a shiny, reflective finish, while matte provides a smooth, non-reflective surface. Soft-touch lamination has a velvety, tactile feel and adds a luxury element to your printed materials. Lamination is commonly used on high-use items like brochures, menus, and business cards, where you require both durability and aesthetic appeal.

Related services

As a leading provider of high-stakes exams and examination materials, we understand the vital role exams play in shaping...

When it comes to fulfilment, we take printed products, or supplied items, and either pack them singly, or collate them together...

By embracing the latest digital technology, we add a personal touch to your marketing materials. We can apply variable-data...

Our modification services include producing modified large print and creating interactive PDFs for candidates with various needs...

Typesetting is more than arranging words on a page. It’s the art and craft of selecting the right font, spacing, and layout to...

As proofreading is the final stage of content creation before your files go to print, it’s the last chance to catch any issues before...